ULTRA Series Dielectric Mirrors

Alluxa Product Line

ULTRA Series Dielectric Mirrors

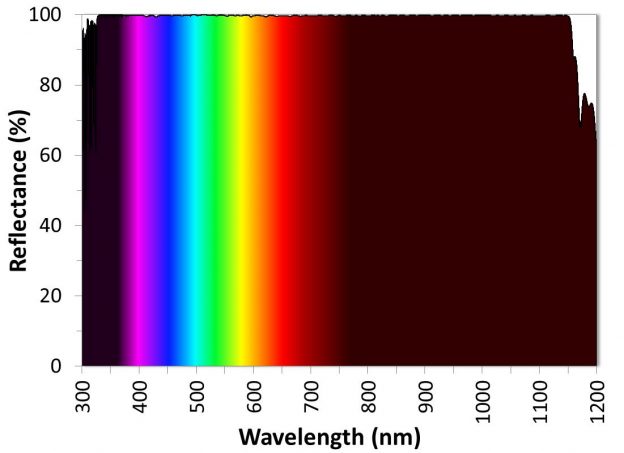

Figure 1. ULTRA Series high-reflectivity dielectric mirror with broadband reflection from the UV to the IR.

Alluxa’s ULTRA Series of high-reflectivity dielectric mirrors provide close to 100% reflection over a broad or precise range of wavelengths. Each hard coated, thin-film dielectric mirror is resistant to laser damage and all will boost instrument performance by preserving light source intensity.

Depending on the wavelength ranges and requirements of your system, ULTRA Series dielectric mirrors can be custom designed to meet one or more of the following challenging specifications:

- Up to 99.5% reflection

- Up to 99% transmission

- 10/5 Surface quality

- Reflection or tranmsission wavelength ranges can be specified from the UV to the mid IR

Ultra-flat mirrors for imaging and laser applications

All ULTRA Series dielectric mirrors can be custom specified to be ultra-flat in order to minimize distortion and maintain optimal performance in imaging and laser-based fluorescence systems. Integrating ultra-flat mirrors into these systems will result in crisp images, minimal focal shift, and accurate quantification of target molecules. Ultra-flat mirrors can be custom specified with better than 0.1 wave PV / inch flatness when measured at 632.8 nm.

Dispersion controlled mirrors for use with femtosecond lasers

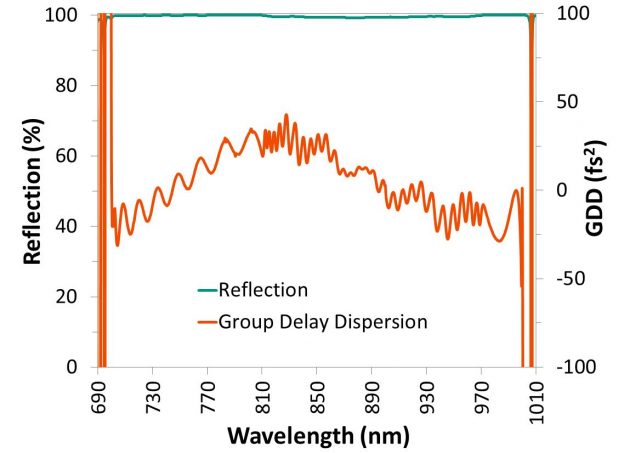

Figure 2. Low dispersion thin-film mirror with GDD less than ± 45 fs2 across a broad reflection range.

ULTRA Series dielectric mirrors can also be specified to control group delay dispersion (GDD). Controlling GDD is necessary when reflective optical components are integrated into instruments that utilize femtosecond lasers. When a femtosecond laser is reflected off of GDD controlled mirrors, the laser pulse intensity is preserved and dispersion is minimized, resulting in bright, crisp images with negligible distortion. This is essential for many non-linear optical (NLO) applications such as multiphoton fluorescence microscopy (MP), second and third harmonic generation microscopy (SHG and THG, respectively), and two-photon excitation stimulated emission depletion fluorescence microscopy (2PE-STED).

Because they are used with ultra-short pulsed lasers, GDD controlled mirrors are also specified with a high laser damage threshold. This ensures that they will maintain optimal performance over a long period of time.

Quality and consistency from an innovative thin-film coating process

Alluxa thin-film optical interference filters and dielectric mirrors are all hard-coated using our SIRRUS™ plasma deposition process on equipment that was designed and built by our team. This allows us to reliably and repeatedly produce the same high-performance thin-film mirrors over several different coating runs, which translates to consistent performance across all of your systems.