Temperature Dependence

Interference filter spectra are temperature dependent. Extreme temperatures result in the expansion or contraction of the thin-film layers, resulting in a red shift with increasing temperature and a blue shift with decreasing temperature. This shift can be dramatic unless the filter has been specified and designed to operate in harsh environments, and is an especially important consideration for ultra-narrowband interference filters.

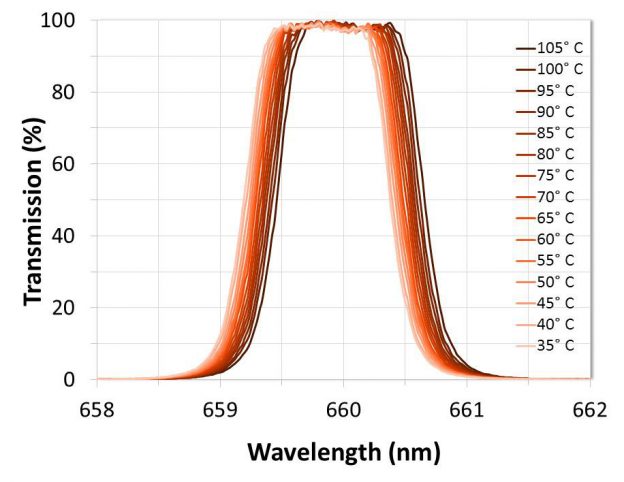

Temperature dependence is commonly specified in terms of a maximum tolerable temperature-dependent wavelength shift, or thermal coefficient, usually given in units of pm/°C. The temperature dependent wavelength shift for Allxua’s hard-coated filters is generally between 2pm/°C and 5pm/°C in the operating temperature range of most instruments (Figure 1) but will depend on the substrate material and filter design.

Figure 1: Measured thermal shift of a narrowband optical filter when heated from room temperature to 105°C.

Thermal stability can be improved even further by modifying material ratios and other design properties, or by choosing a substrate material that has a higher Coefficient of Thermal Expansion (CTE) than the CTE of the coating. Post deposition annealing can also aid in both thermal and chemical stability. During this process, the thin-film layers are thermally expanded while the materials are further oxidized, resulting in a reduction of coating stress.

Why Alluxa?

Alluxa’s team of experts has delivered key innovations to the field of optical thin-films. In addition to designing and constructing all of our own custom optical thin-film coating equipment, we invented a novel plasma deposition coating process that both increases the performance of our optical filters and decreases the time it takes to produce them.

By combining these innovations with state-of-the-art automation, proprietary control algorithms, and precision monitoring during the coating process, we are able to deliver low-cost, high-performance, custom thin-film optical filters for any application.