Flow Cytometry Filters

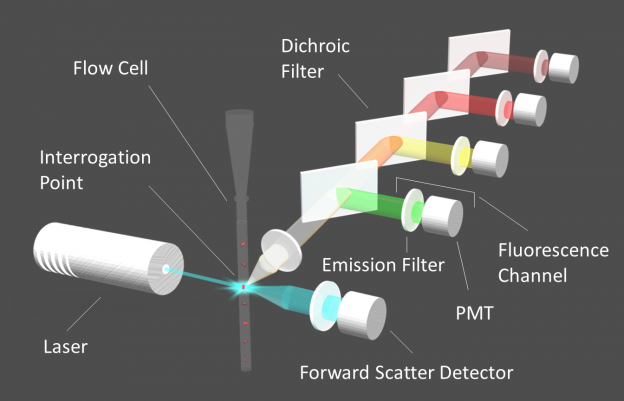

Figure 1. Diagram of a flow cytometer.

Image credit: Alluxa

Used across a variety of biological disciplines, fluorescence-based flow cytometers rapidly and accurately quantify cells and cellular components. As one of the most important components of these systems, flow cytometry filters must be specifically designed to maximize signal-to-noise ratios while minimizing crosstalk between fluorophores.

Flow Cytometers

Flow cytometers are fluorescence-based systems that are used to quantify and sort cells that have been tagged with one or more fluorophores. Individual cells are first labeled with fluorescent tags, and then suspended in a physiological buffer, called sheath fluid, before they are injected into the fluidics system of the instrument. Inside the flow cell of the fluidics system, the suspended cells are arranged in a single-file row by means of hydrodynamic focusing. As the line of cells moves through the flow tube, each cell flows past one or more interrogation points where a laser beam is used to excite the fluorophores in the sample. The fluorescence emission signals from each fluorophore are then isolated by their respective emission filters and directed to the appropriate detector by means of a series of dichroic filters (Figure 1).

Flow cytometers use photomultiplier tube (PMT) detectors that convert light into electric current, which is then digitized for analysis purposes. As each cell flows past the interrogation point, an electric pulse is ultimately generated that corresponds to the signal intensity at each point in the cell’s path over time as it passes the laser beam. Once the cell flows completely past the beam, the signal intensity returns to baseline until the next cell reaches the interrogation point. The pulses are then quantified in order to give an accurate count of cells or specific cellular components. In the case of cell sorters, cells are directed to appropriate vials based on which fluorophores are detected.

Flow Cytometry Filters

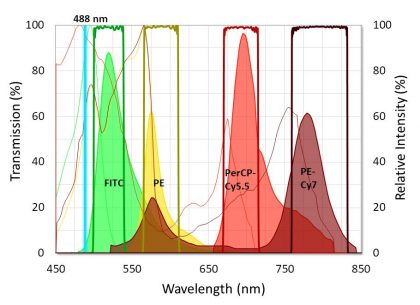

Flow cytometers use fluorescence emission filters and dichroic filters that are specifically designed to isolate the relatively weak emission signals of the target fluorophore for each channel, while blocking out the signals of neighboring fluorophores (Figure 2). Flow cytometry emission filters must have passbands with high transmission and low ripple that capture the emission peaks of each fluorophore. Emission filters must also be designed with very steep edges and relatively narrow bandwidths in order to block as much of the overlap between fluorophore emission as possible. Wide-range out-of-band blocking should extend beyond OD6 (-60dB or 0.0001% transmission), particularly at the excitation laser line.

Figure 2. Graph showing the ideal placement of flow cytometry filters used with four standard fluorophores. Fluorophore emission intensity is shown after excitation with a 488 nm laser.

Dichroic filters for flow cytometry must be designed with steep edges and minimal polarization splitting in order to efficiently direct the target fluorescence emission signals to the correct detector. Flow cytometry dichroic filters should also have a surface flatness specification that is suitable for use with lasers in order to minimize spot size distortion and beam deviation caused by reflected wavefront error (RWE).

Additionally, since the emission light will be transmitted through multiple filters prior to reaching the detector, all flow cytometry filters should be specified to produce minimal transmitted wavefront error (TWE) to prevent signal distortion. And all filters in these systems should have a high laser damage threshold (LDT).

SIRRUS™ High-Performance Hard Coating

Our flow cytometry filters are all hard-coated using an innovative SIRRUS™ plasma deposition process. This allows us to reliably and repeatedly produce high-performance laser clean-up, emission, and dichroic filters with steep edges, transmission that is typically greater than 95%, precision wavelength control, low TWE, and a high LDT. Our dichroic beamsplitters for flow cytometry are manufactured to achieve surface flatness that is 2λ P-V per inch or better, depending on the specific requirements of your flow cytometer.

Our knowledgeable engineers will work with you to design the optimal flow cytometry filters for your system based on your fluorophore selections, excitation lasers, and system configuration.

Why Alluxa?

Alluxa’s team of experts has delivered key innovations to the field of optical thin-films. In addition to designing and constructing all of our own custom optical thin-film coating equipment, we invented a novel plasma deposition coating process that both increases the performance of our optical filters and decreases the time it takes to produce them.

By combining these innovations with state-of-the-art automation, proprietary control algorithms, and precision monitoring during the coating process, we are able to deliver low-cost, high-performance, custom thin-film optical filters for any application.